TOP CNC MACHINE TOOLS FOR 2022

Are you looking to make any parts? CNC machines are the best choice because they are flexible and extremely accurate. CNC machines are highly accurate because of their computerized attributes.

The endless number of cutting tools available to CNC machines adds to their versatility. This article will explain the functions and tools that can be used in conjunction with CNC machines.

Before you purchase, hire, or run any business dealings with CNC machine sellers, it is important to have a clear understanding of the tools.

Here are the top CNC machines to use in 2022 for any project, personal or business.

Face Mill

The material must be prepared before you can begin major milling operations. Face mills can be used to create flat sections of a piece without fussy cutting.

A Face mill is a machine that has a solid structure and several compatible cutter inserts. These can be swapped as needed. Side and face cutters are best used for complex and difficult operations. They allow you to cut a groove or slot in the material as well as its side walls.

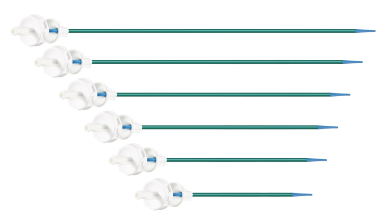

Drill Bits

Drill bits are made up of a shaft and a conical point that can be used to cut with one or more flutes. Flutes are the spiral grooves that run down the outer portion of the tool. There are three types of drill bits: ejector, center and twist.

Each drill bit has a different function. The center drill bits can be used to make small holes that can then later be perfectly drilled with a twist drill. The ejector drill can be used to drill deep holes.

End Mill

Although they look similar to drill bits, end mills are much more versatile in their actions. End mills can have up to eight flutes at the sides and ends, which allows them to remove many materials.

End mills are used for many cutting applications.

Side milling

It’s used to machine an edge surface of a piece.

Face milling

This is used to mechanize the topmost face of a piece.

Slot milling

Used for mechanizing double-edge or two-edge surfaces

Plunge Milling

This is used to mechanize the Z-axis.

Ramping

These are used to simultaneously mechanize in both the axial or radial directions, creating a pointed tool path. You can choose from either a linear or circular ramping tool path.

If you need to cut through material without drilling a hole, the end mill is your best choice.

Reamers

Reamers (we have to admit that we had to Google what reamers were, here is Britannica) can be used to extend predrilled holes to fit a particular measurement. They also give the surface a nice finish. This helps to ensure that the hole is correct in size and shape.

You can use a drill bit that is smaller than 31/64” to make a hole in 1/2 inch of material. Then, use a reamer to widen the hole to 1/2 inch.

Gear Cutters

The name implies that gear cutters are essential in the production of gears for manufacturing companies. The gear cutters can be used to make a wide range of gears, including helical, worm and screw as well as spur, bevel, and screw gears.

Thread Mills and Taps

Thread mills are CNC trimmers that are used to cut threads. Because they serve the same purpose, thread mills can be compared to taps.

Taps are limited to cutting internal threads. CNC machines equipped with thread mills have the ability to cut both external and internal threads. When thread mills are needed to penetrate hard metals or asymmetrical areas, one should choose a thread mill.

Hollow Mill

Hollow mills are a tube-like tool for cutting. They have three to five cutting edges that encircle and spin around a cylindrical-shaped workpiece. This cutting tool is efficient and quick to produce a reliable prethread diameter. Drill press work can also use hollow mills to make predictions that require a particular position.

Fly Cutters

Fly cutters can be used to create amazing surface finishes. The CNC rotary tools rotate counterclockwise and move along the material’s surface, creating speckles and shine finishes.

Fly cutters are less expensive than face mills and have a smoother finish. Fly cutters are a good option for plane surfacing.

Slab Mill/ Plain Mills/Slab Cutters

Slab mills can also be called plain mills, slab cutters, and are used for cutting flat surfaces. Slab mills are equipped with teeth at their edges and can quickly produce narrow or wide cuts.

Center Spotting Drills

The center spotting drills, which are stubby, are used when drilling precise conic holes. This helps to ensure that the drill bits do not “walk” during drilling and operation at imprecise positions. There are also collective spotting-countersink drilling tools that can be used to counter sinking and screw clearance holes.

Tool Holders

Solid End Mill Holders

End mills made from Weldon flat material are protected by a set screw. This provides minimal concentricity loss and a firm grip.